|

|

The picture below is the physical product picture of the 150L barrel sandblasting machine.

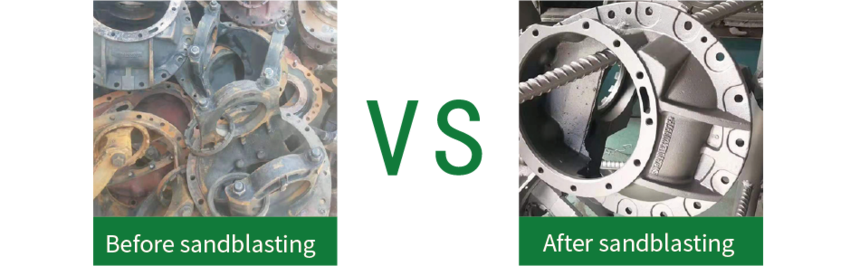

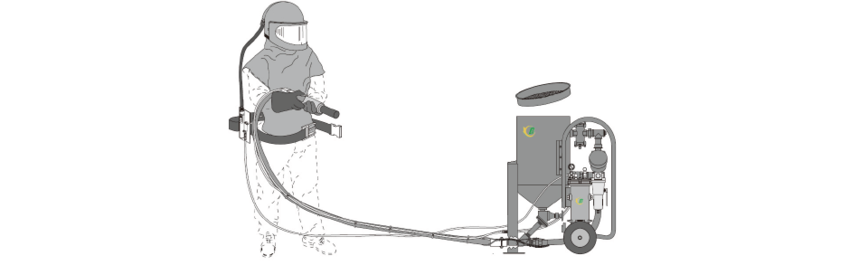

working principle Barrel type standard manual sandblasting machine (sandblasting tank) is a mechanical equipment that uses compressed air to spray abrasives (copper ore, iron sand, emery, etc.) onto the surface of the object to be cleaned. The abrasive in the sand tank enters the sand valve under the action of compressed air and mixes with air. The sandblasting pipe is sprayed from the nozzle to the surface to be cleaned for surface rust removal, descaling, residual sand removal, oil removal and other attachments, so as to achieve the ideal effect of enhancing the coating surface adhesion, surface strengthening and decoration. Machine characteristics Adopting domestic and foreign technology, using straight-through sand blasting valve to completely solve the clogging of the abrasive. The speed of the blasting outlet can reach 200M/S. The sand valve is an important part of the sand blasting machine. Its main function is to control the opening and closing of the sand. Close, steplessly adjust the size of sand flow during sand blasting. The quality of the sand valve directly affects whether the sand blasting machine can work normally. This type of sand blasting machine adopts the large sand valve produced by our company. The valve adopts foreign technology and has the characteristics of reliable quality, convenient adjustment and simple maintenance. A structure widely used in various countries in the world; the opening of the sand valve is controlled by air pressure, and its action process is that when the control port has an air pressure signal, the piston of the sand valve drives the valve stem to rise, and the sand valve opens. Position, the opening amount of the sand valve can be adjusted to control the sand flow rate. The opening amount of the sand valve can be adjusted steplessly. The valve stem and valve sleeve in contact with the sand in the sand valve are made of hard gold tungsten carbide, which improves The service life of the sand valve is improved. Scope of application Used for cleaning steel structure, molds, fitness and amusement equipment. Glass, stone stele carving, ship building, bridges, mines, machinery, petroleum pipelines, water conservancy projects, port construction, etc. rust removal, spray processing, descaling, and burrs can also be used for spraying and electroplating pretreatment processes to improve coating ( All surface treatments for the adhesion of the plating) layer surface.

|