|

|

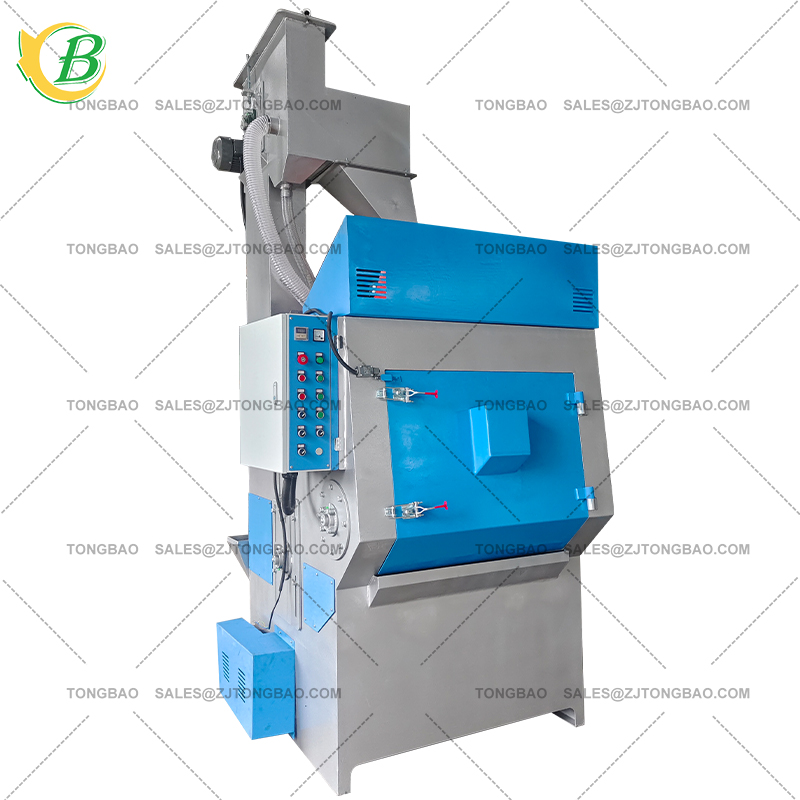

Tumble belt blast machine are suitable for the derusting, deburring, roughening, or cleaning of robust work pieces of any size that are suitable for tumbling. Depending on the type of system, the work pieces are processed in either batches or in continuous operation. Depending on the system type, the machines are used for blasting transmission parts, forged parts, and light metal components. In the blasting area, the work pieces are constantly in motion. Through the perforated tumble belt, which is made of rubber as standard (but optionally also of steel), the parts are circulated and simultaneously blasted with the aid of turbines.

Tumble belt blast machine TBQ326 Diameter of track end disc: φ600mm Speed of crawler end disc: 3.6r/min Track drive motor power: 1.5kW The largest single piece weight of the workpiece to be cleaned: 10kg The maximum load capacity of the roller (easy to roll parts): 200kg Productivity: 600~1200kg/h (gray castings) Turbine: Speed: 2930r/min Impeller diameter: φ360mm Shot blasting volume: 120kg/min Shot blasting power: 7.5kW Air volume of dust collector: 2200m3/h Fan power: 2.2kW Total installed capacity: 11.50kW Machine dimensions (L×W×H): 2080mm×1810mm×3300mm Total weight of the machine (approximately): 2000kg |