|

Walnut shell particles walnut sand abrasive

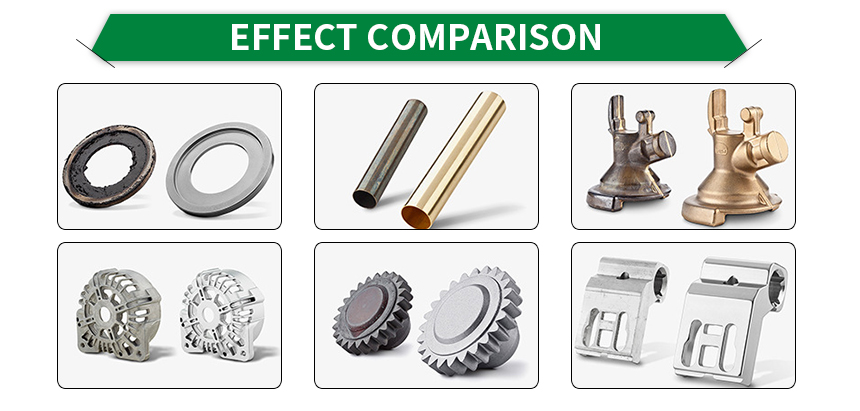

Walnut shell abrasive has high hardness, abrasion resistance, good pressure resistance, pressure resistance of 23.4KgF, stable chemical properties, does not dissolve in acid and alkali, strong adsorption and dirt interception ability, adsorption rate of 27-50%, good hydrophilicity and resistance Oil immersion, specific gravity g/cm31.25, slightly larger than water, filling specific gravity 0.85g/cm3, easy to backwash and regenerate, compared with other filter media, it has the advantage of directly using pre-filtered water backwash, low operating cost, The backwash intensity is low, (6.71/S. m2), and the filtration rate is fast (24—26/n) and the effect is good. The treatment effect on the oil field impregnable water is remarkable, the oil is removed up to 95%, and the oil content is reduced to less than 5mg/l. Application areas: 1. Walnut shell particles can also be used as abrasives, which can be used to clean and polish metals, alloys, molds, instruments, motors, plastics, gold and silver jewelry, glasses, watches, and buttons, etc.; in the sandblasting industry to remove paint stains and rust Stains, chemical substances, etc.; 2. Walnut shell abrasives are produced in accordance with national industrial standards and have the advantages of good durability, good polishing and grinding effects, and a wide range of applications, suitable for various basic metals such as zinc, aluminum, copper, copper alloys, brass, Bronze, stainless steel, steel, titanium and other rough, medium and fine rolling to mirror grinding effect: 3. Walnut sand abrasive is suitable for deburring and polishing in the glasses industry, textile industry, mechanical processing, hardware, bearing and other industries; it is also a polishing material and can be used with various polishing, sandblasting and cleaning equipment. Suitable for grinding and polishing of spectacle frames, spectacle accessories and other hardware parts.

Walnut shell abrasive parameters

|

||||||||||||||||||||||||||||||||||||||