|

Shot Peening Technology of Gear SurfaceShot peening is a controlled shot peening technique, which is different from shot peening. Shot blasting aims to remove oil stains, oxide scale, rust and machining burrs on the surface of the workpiece. The shot peening of the gear surface is mainly by means of the high-speed moving projectile impacting the surface of the part, causing it to undergo elastic plastic deformation, resulting in beneficial changes such as residual compressive stress, work hardening and structure refinement, so as to improve the bending fatigue strength of the gear And contact fatigue strength is an important way to improve gear anti-seizure ability and increase gear service life.

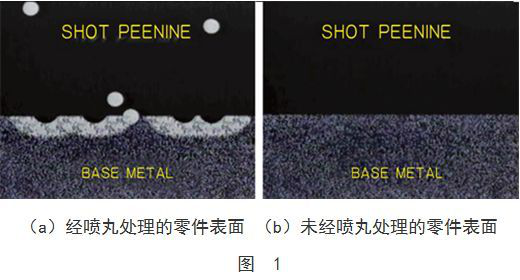

1. Pill strengthening mechanism and its application as spray 1. Shot peening treatment can improve the stress distribution on the surface of the part The residual stress after shot peening comes from the uneven plastic deformation of the surface and the phase transformation of the metal structure, of which the uneven plastic deformation is the main cause. After shot peening, a large number of plastic deformations in the form of pits are produced on the metal surface, the dislocation density of the surface layer is greatly increased, and the phenomenon of sub-grain boundaries and grain refinement appears. As shown in Figure 1. After shot peening, part of the retained austenite on the surface of the gear will become martensite, and compressive stress will be generated due to the volume expansion during phase transformation, so that the retained austenite field on the surface changes toward greater compressive stress. Improve the fatigue strength of gears. Through shot peening, the heat treatment stress can be eliminated, the surface oxide scale can be removed, the notch sensitivity of the parts can be improved, and the residual stress that is prone to part failure can be converted into compressive stress, effectively limiting the generation and expansion of crack sources, and a large extent Improve the fatigue life of parts. 2. Shot peening can form a high compressive stress layer on the surface of the workpiece Because shot peening increases the surface compressive stress and significantly improves its fatigue performance, it is more effective for workpieces that bear high-frequency fatigue loads. The residual compressive stress formed by shot peening can offset part of the applied load. During shot peening, small-sized spherical steel shots hit the surface of the workpiece to form a compressive stress. The impact of each shot will cause the metal to produce a certain degree of plastic deformation, and the surface cannot be completely recovered and a permanent compressive stress state is formed. As a surface strengthening process, shot peening can form a residual compressive stress on the surface that is equivalent to 55% to 60% of the material's tensile strength limit, and the surface of the workpiece is where cracks are likely to occur. For carburized and hardened gears, the resulting compressive stress can reach 1177~1725MPa, which can greatly improve the fatigue performance. The depth of the compressive stress layer is a function of shot peening strength (or shot peening energy) and increases as the size or velocity of the shot increases.

2. Shot peening process parameters The shot peening process has higher requirements on the shape, size and hardness of the shot. The shot peening strength and surface coverage are used to control the shot peening process, and the residual stress and fatigue test are used to detect the surface strengthening effect. Shot peening process parameters include shot material, shot diameter, shot speed, shot flow rate, shot angle, shot distance, shot peening time and coverage, etc. The change of any one of the parameters will affect the shot peening strength to varying degrees, that is, the strengthening effect .

3. Application of shot peening technology 1. Improve the surface hardness of carburized gears Example 1: The shot blasting equipment of FAW Heat Treatment Branch adopts the German TR5SVR-1 stress shot peening equipment. The shot peening process is: steel shot with diameter of ¢0.8mm, shot peening time 9min, shot peening speed 2800r/min. The gear material is 22CrMoH steel, which has been carburized, quenched and tempered. After shot peening, the gear surface structure is refined. The retained austenite content of the surface layer is about 10% lower than the retained austenite content of the workpiece without shot peening. The change is within 0.15mm from the surface. Obviously; the surface hardness of the gear after strengthening shot peening is increased by 0.5~2HRC. 2. Increase the residual compressive stress on the gear surface and improve the surface microstructure Example 2: The second-speed driven gear of the Santana car transmission is carburized, quenched and tempered. Shot peening adopts impeller type shot peening machine, shot peening speed 2900r/min, shot hardness 57HRC. The results of the shot peening test are as follows. (1) The surface microhardness of shot blasting parts is significantly increased, which is the result of the combined effects of high residual compressive stress, work hardening, and microstructure change (refining). The significant reduction of retained austenite also contributes to the increase in hardness. Contributed. (2) Due to shot peening, the retained austenite in the surface of the workpiece becomes martensite, which can be used to increase the surface hardness. The martensite needles are obviously smaller and denser than unshot peened parts, and play a role in refining the substructure of martensite. It is beneficial to increase the residual stress, thereby improving the fatigue performance of the gear. 3. Improve the fatigue life of gears Example 3: FAW used the enhanced shot peening process to carry out the fatigue life test on the first gear of the "Jiefang" brand automobile transmission, which significantly improved the fatigue life of the gear. As shown in Table 1. In order to improve the fatigue life of the "Jiefang" brand driving helical gear, a large arc hob is used to cut the teeth. Increasing the gear fillet can increase the life of the driving helical gear from 208,300 times to 695,400 times. If strengthened shot peening is used again, Increase its fatigue life to 2.109 million times. Table 1 The effect of shot peening on the fatigue life of the first gear of "Jiefang" brand transmission

4. New technology of shot peening 1. Hard shot peening technology of gears (1) Hard shot peening technology Hard shot peening is different from conventional shot peening, but uses 700HV high-hardness steel shot for high-strength shot peening, and makes the A-type test piece produce an arc height of 0.6mm or more, forming a larger residual compressive stress and obtaining high fatigue strength . Suitable for high-quality carburizing steel (such as DSG1 steel, the Si content is reduced to less than 0.15%, which greatly reduces the internal oxidation phenomenon and non-martensite; reduces the grain boundary brittle element P content <0.015%, and increases the Mo content to 0.4 % And greatly improve the toughness of the carburized layer), it is effective in eliminating carburizing defects such as internal oxidation and ensuring the toughness of the carburized layer. (2) Twice shot peening (double shot peening) technology For gears with carburizing and quenching hardness above 600HV, it is difficult to achieve higher compressive stress through normal shot peening. For this reason, secondary shot peening is used to improve the fatigue strength, that is, first use 700HV high-hardness shots for high-strength shot peening (such as 0.6mm steel shot), and make the A-type test piece produce an arc height of more than 0.6mm to obtain a certain depth Surface strengthening layer, and then use small low-strength small shots (such as 0.08mm steel shot) for a low-strength shot peening, which can form residual compressive stress on the surface and subsurface of the workpiece. The purpose of the second shot peening is to reduce the surface work hardening, improve the surface roughness, and increase the surface compressive stress, that is, to further improve the fatigue performance of the gear. This technology belongs to cold work processing. 2. Application of new hard shot peening process Example 1: Spur gear, material DSG1 (chemical composition (mass fraction, %) is 0.20C, <0.15Si, 0.70Mn, <0.015P, 0.015S, 1.00Cr and 0.40Mo) and SCM420, after carburizing, quenching, and tempering Fire treatment. Finally, a centrifugal shot peening machine and 0.8mm cast steel shot (chemical composition 0.85C-1Si-1Mn) were used for shot peening, and the shot peening strength was 0.45mmA and 0.7mmA arc height respectively. The former belongs to conventional shot peening, while the latter belongs to hard shot peening. The gear fatigue test is carried out on a current-consuming gear fatigue test machine. (1) Shot peening treatment parameters and inspection results The test gear shot peening parameters are shown in Table 2. It can be seen from Table 2 that the tooth root fatigue strength of hard shot peened gears is higher than that of conventional shot peening. The surface hardness and residual compressive stress of hard shot peened gears increase while the degree of retained austenite and internal oxidation decrease. Table 2 Carburizing results and shot peening parameters of test gears

(2) Comparison of hard shot peening, small shot peening and secondary shot peening After shot peening, the maximum residual compressive stress value is about 0.05mm below the surface, but the surface is below this value. To solve this defect, small shots (diameter <0.1mm) are used for low-strength shot peening . Three kinds of shot peening process parameters are shown in Table 3. Hard shot peening gives the highest surface hardness, followed by secondary shot peening and small shot peening. Shot peening of small pellets makes the gear surface get very high compressive stress, reaching 1.2GPa. The second shot peening treatment obtains the highest fatigue strength. Compared with the carburized and quenched gear, the fatigue strength is increased to 1.5 times. The carburized gear is left with cutting marks, which all disappear after shot peening, and the gear surface roughness is improved. Since the machining tool marks may become stress concentration points, the improvement of the machining surface during shot peening is also a reason for improving the fatigue strength. Table 3 Three kinds of shot peening process parameters

Tongbao Technology is dedicated to provide our customers with high-quality products and services!! We can customize CNC automatic sandblasting equipment for you! ! ! Contact Email:sales@zjtongbao.com |