|

|

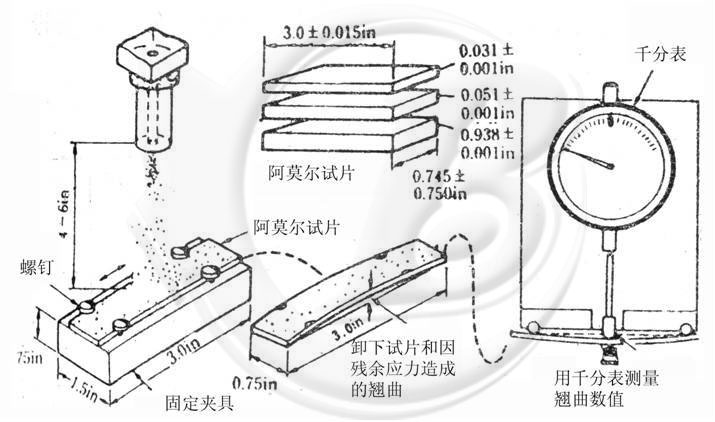

Application of Residual Stress Test in Shot Peening Process MonitoringShot peening, as an important strengthening process for auto parts, is widely used in automobile production. In the past, the arc high film was used to control the shot peening effect, and the result did not match the actual product life. After that, an X-ray stress meter is used to test the residual stress on the product surface and subsurface. According to the technical requirements, the shot peening process with the residual stress meeting the technical requirements can be used in production. The parts involved are very wide, such as springs, gears, torsion bars, stabilizer bars, connecting rods, crankshafts and so on.

X-ray stress analyzers have become equipment in the field of non-destructive testing today. Its light and exquisite design greatly expands the field of use of the equipment, enabling the equipment to go out of the laboratory and become effective and feasible for use in the field or even outdoors. Main application areas: Aerospace, aviation, shipbuilding, weapons, electric power, petrochemical industry, boilers and pressure vessels, metallurgy, machinery manufacturing, nuclear industry, petroleum, scientific research institutions, universities, etc. X-ray stress analyzer software -Operating System: Windows -X-ray generation and control -Real-time monitoring of high-voltage systems -Multiple X-ray exposure modes -Simultaneous measurement, calculation and other functional operations -Multi-point d-sin2Ψ exposure mode, cross-correlation method to calculate peak displacement -Rich material database -The measurement error of stress-free iron powder can be controlled to within ±6.9MPa Tongbao Technology is dedicated to provide our customers with high-quality products and services!! We can customize CNC automatic sandblasting equipment for you! ! ! Contact Email:sales@zjtongbao.com |