|

Advantages of robot automatic sandblasting machineAccording to market demand, in the future, we will closely integrate industrial robot technology, vigorously improve the automation and intelligence of sandblasting machines, and focus on liberating labor, improving productivity, and reducing the production cost of enterprises for the purpose of accelerating the surface treatment industry in China’s Industry 4.0 Comprehensive layout of the times. The use of robots instead of manual sandblasting has the advantages of automation, high efficiency, stable operation, high sandblasting accuracy and safety. Today, when the arduous and dangerous manual blasting is gradually replaced by automatic blasting technology, the robot blasting room cleaning program has become a general trend. Automation: After inputting the workpiece code, the robot can automatically identify the workpiece of various specifications and automatically complete the sandblasting operation, which is completely covered at one time without manual assistance. High efficiency: The sandblasting cleaning robot can work tirelessly, which is many times more efficient than traditional manual sandblasting. And the uninterrupted operation in the difficult environment has created the efficiency of the sandblasting cleaning robot.

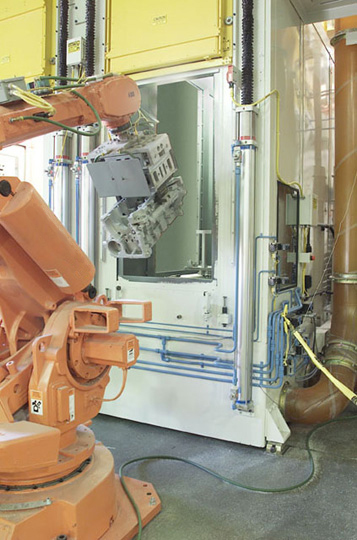

Bridge type sandblasting robot system Stable operation: The robot adopts programming control and runs stably. There are no unstable factors such as manual sandblasting, fatigue, misjudgment, and emotions. The robot is equipped with an anti-collision device, which will automatically stop resetting and give an alarm when it encounters an abnormal collision. High sandblasting accuracy: The robot has high sensitivity, stable operation, and repeat path accuracy of 0.1mm, which is far beyond the reach of humans. The surface quality of the workpiece after sandblasting is very ideal, with good cleanliness and roughness, and can be directly painted or subjected to other treatments. The proper blasting pressure, the proper blasting distance between the nozzle and the workpiece, and the accurate blasting angle will directly affect the roughness and cleanliness. The blasting robot adopts shot materials and air pressure suitable for the surface requirements of the workpiece. The distance and angle of the nozzle can be adjusted continuously to ensure the high quality requirements of customers. Safety: Manual sandblasting is very difficult and dangerous and harmful to health. The operator has to bear the intrusion of noise and dust, and the body is also prone to overwork. If you deal with large pieces of equipment, you also need to use ladders and workbenches, and the work becomes very dangerous. The operator needs to put on a heavy suffocating protective cover to avoid the damage of the pellets flying at a speed of 200 meters per second. Accidents and work injuries often occur in manual sandblasting, and production is often delayed because of this. There are fewer and fewer people willing to engage in this kind of laborious and dangerous work, and personnel transfers are very frequent. Sandblasting robots can solve all the above-mentioned problems. When the operator manually operates the robot, he sits in an air-conditioned humanized operation cabin and controls the robot through the joystick. When the robot automatically cleans the workpiece, the operator only needs to monitor the robot in the control room outside the blasting room.

|